Initial situation: lost sight of the goal

For years, sales and earnings were on the rise. But the goals of the medium-sized special machinery manufacturer grew even faster. A strategy was developed and extensive investments were implemented with external financing. Sales activities and development activities to utilize the capacities created, on the other hand, remained vague. There was no strategic planning and thus no controlling of strategic goals. When sales stagnated instead of growing, it was no longer possible to compensate the losses of individual products and the costs of inefficient processes and structures. Also under pressure from financiers, HANSE Consulting worked with the mechanical engineering company to develop a concept for restructuring so that the turnaround could succeed.

Every concept for a restructuring is unique – the only way to turnaround succees

Even though there are typical triggers and measures in a crisis, crises are always individual. And in this case of clearly missed growth targets, an appropriate capacity adjustment suggested itself at first glance. While developing the concept, the lack of gross margins due to unachieved growth was joined by particularly high losses from a newly developed product line, escalating quality costs, technologically inefficient production processes and overly expensive procurement. How could this have happened?

Although the goals were actually known and measures were discussed in the management team, the losses and their causes continued. Commitment and personal responsibility for achieving goals and implementing measures was weak in the management team, partly because numbers, data and facts (NDF) were often lacking.

The concept for restructuring developed jointly by HANSE Consulting and the machine builder focused on the following core measures:

- NDF: Improvement of performance-based controlling, introduction of strategic and personal KPIs. Monthly assessment of target achievement and development of KPIs in the management team as well as consistent action tracking.

- Stop-loss concept for the loss-making new product division: Initiation of a sales process due to persistent losses.

- Sales management: conceptual design of sales management and controlling as well as implementation of a new CRM system.

- Order processing: restructuring of the organization and the processes of the entire project processing (order-related make-to-order production).

- Production: reduction of manufacturing costs by adapting manufacturing processes.

When implementing the measures for the restructuring, it depends on the specific activities for the turnaround – the following are some examples:

Restructuring measure in production:

To save on labor costs and avoid shortages of skilled welders, they had invested in a welding robot. Our review of production times and costs, including upstream and downstream steps, showed that the entire process was already more expensive than before at the variable cost level. Due to the single-order production, each part had to be reprogrammed and taught. Promising optimization measures for the automated welding of the previously planned range of parts could not be developed, least because of the quantities involved and the geometry of the welds on the sheet metals. A review of the machine builder’s other parts spectrum revealed that the lids previously purchased as turned parts could be manufactured much more cost-effectively using the adaptive technology of buildup welding and the existing welding robot. After successful pressure vessel approval of the parts, the manufacturing costs for these could be reduced in a double-digit percentage range.

Restructuring order processing:

Despite the use of specialized order planning software with an interface to the ERP system and detailed capacity planning, more than 80% of orders were delayed. Although the management information system indicated at an early stage which process step in order processing would lead to delays, the causes remained in the dark.

It turned out that the processing of orders in the design department, which was assigned to the sales department and was crucial for meeting deadlines, had not been fully integrated into the order planning software. The agreed delivery times for drawing parts could not be met, also due to the delayed design. Express surcharges and the selection of faster manufacturing processes from suppliers led to excessive procurement costs of several 100 thousand euros annually. For this reason, responsibility for order design was reorganized and the design process was fully mapped in order planning. This made it possible to identify imminent delays at an earlier stage. The analyses also made clear, that in many cases customer requested changes and adjustments caused delays, yet the delivery date was not renegotiated. With an additional digital workflow and daily change analysis of the order dates, the postponements could be made more transparent and necessary countermeasures could be initiated earlier.

As a result, capacity planning was restructured and delivery reliability improved significantly to over 90%. Among other things, we coarsened the overly differentiated capacity units in line with the overall competence profile of the employees and carried out the adjustment of capacities at shorter intervals.

Restructuring of the product portfolio:

Despite continued losses, the company initially held on to the new product division. It was difficult to part with a product innovation that had been launched with great expectations and a great deal of development effort.

HANSE Consulting agreed together with the company on a stop-loss mark, below which the sale or liquidation had to take place. As expected, this occurred after only a few months. Although there were few strategic investors for the technological niche product and financial investors were hardly to be considered, our HANSE M&A division succeeded in shaping a bidding competition. The successful sale as part of an asset deal not only improved the Group’s earnings by around EUR 1.0 million p.a., the inflow of the purchase price also significantly strengthened the company’s liquidity.

Result of the restructuring – The turnaround was achieved!

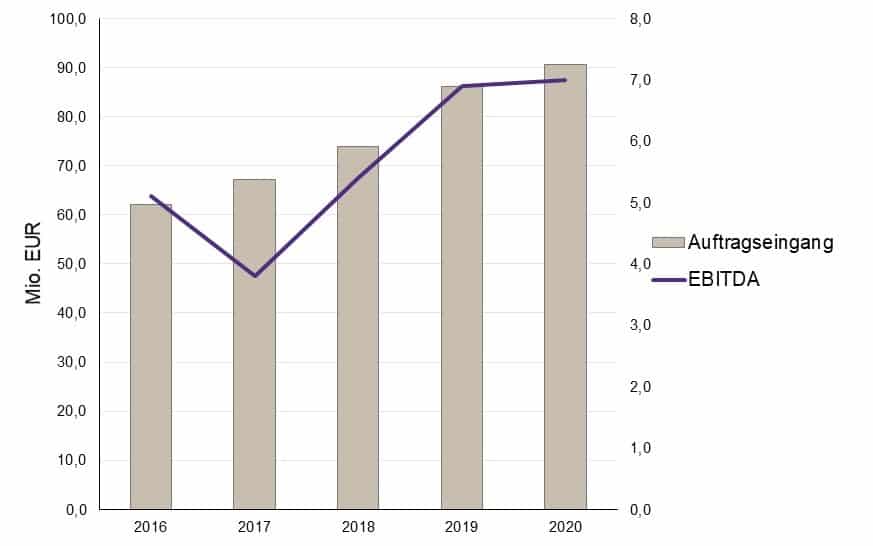

Also because the order intake was brought back on a growth track, EBITDA and EBT were lifted back to pre-crisis levels.

The original growth targets were nearly achieved by 2020. As a result of the restructuring measures developed in 2018 and largely implemented by mid-2019, a positive company result was already achieved again in 2019, so that the financing of the group of companies could also be secured.

From the concept to the realization of the measures: Restructuring is always teamwork that can only succeed together.

Talk to us

the experts at HANSE Consulting are here for you!

![[EN ]Hanse Consulting](https://en.hanseconsulting.de/wp-content/uploads/sites/21/2022/06/hc22_logo_350.png)